焦化行業(yè)焦?fàn)t煤氣的技能技術(shù)

由于焦?fàn)t普遍采用了的煙氣余熱回收技術(shù),約有50%~55%的焦?fàn)t煤氣富余,我國許多焦化企業(yè)將剩余的焦?fàn)t煤氣用于發(fā)電。焦?fàn)t煤氣發(fā)電有三種方式,分別為蒸汽發(fā)電(熱電聯(lián)產(chǎn))燃?xì)廨啓C(jī)發(fā)電和內(nèi)燃機(jī)發(fā)電,目前這幾種發(fā)電方式在國內(nèi)均有應(yīng)用,技術(shù)成熟。如果焦化企業(yè)與高電耗生產(chǎn)匹配或與發(fā)供電企業(yè)聯(lián)營,且上網(wǎng)電價合適,焦?fàn)t煤氣用于發(fā)電可作為優(yōu)先選擇的技術(shù)路之一。其運(yùn)行與管理簡便,生產(chǎn)作業(yè)間長,可采取多種方式,企業(yè)收益穩(wěn)定。

Due to the widespread use of efficient flue gas waste heat recovery technology in coke ovens, approximately 50% to 55% of coke oven gas is surplus. Many coking enterprises in China use the remaining coke oven gas for power generation. There are three ways to generate electricity from coke oven gas, namely steam power (cogeneration), gas turbine power, and internal combustion engine power. Currently, these power generation methods are widely used in China and have mature technology. If the coking enterprise matches high power consumption production or collaborates with power generation and supply enterprises, and the grid electricity price is appropriate, the use of coke oven gas for power generation can be one of the preferred technological options. It is easy to operate and manage, has a long production workshop, and can adopt various methods, resulting in stable enterprise profits.

蒸汽發(fā)電,熱電聯(lián)產(chǎn)供熱與發(fā)電兼用

Steam power generation, cogeneration for both heating and power generation

蒸汽發(fā)電由鍋爐-凝氣式氣輪機(jī)-發(fā)電機(jī)組成。該工藝以焦?fàn)t煤氣作為熱源燃燒鍋爐,生成高壓蒸汽,用以帶動汽輪機(jī)發(fā)電機(jī)而發(fā)電。蒸汽發(fā)電技術(shù)過關(guān)成熟可靠。在我國焦化行業(yè)應(yīng)用較廣泛,但其系統(tǒng)復(fù)雜占地面積大啟動時間長。

Steam power generation consists of a boiler, a condensing gas turbine, and a generator. This process uses coke oven gas as a heat source to burn the boiler, generating high-pressure steam to drive the steam turbine generator and generate electricity. The steam power generation technology is mature and reliable. It is widely used in the coking industry in China, but its system is complex, covers a large area, and takes a long start-up time.

焦?fàn)t煤氣用于燃?xì)廨啓C(jī)發(fā)電

Coke oven gas used for gas turbine power generation

燃?xì)廨啓C(jī)發(fā)電是用焦?fàn)t煤氣直接燃燒,驅(qū)動燃?xì)廨啓C(jī)以帶動發(fā)電機(jī)發(fā)電。燃?xì)廨啓C(jī)發(fā)電機(jī)組設(shè)備緊湊占地少效率益好啟動速度快。不過,燃?xì)廨啓C(jī)運(yùn)行一段時間后必須遠(yuǎn)距離運(yùn)回制造廠檢修,因此需要較多的備品,要求工人有較高的技術(shù)素質(zhì)。

Gas turbine power generation is the direct combustion of coke oven gas, which drives the gas turbine to drive the generator to generate electricity. The gas turbine generator set equipment is compact, occupies less land, has high efficiency, good efficiency, and fast startup speed. However, after operating for a period of time, the gas turbine must be transported back to the manufacturing plant for maintenance at a long distance, thus requiring a large amount of spare parts and requiring workers to have high technical qualifications.

燃?xì)?mdash;—蒸汽聯(lián)合循環(huán)發(fā)電技術(shù)(CCPP)

Gas Steam Combined Cycle Power Generation Technology (CCPP)

該技術(shù)的基本原理是將剩余的焦?fàn)t煤氣和回收的高爐煤氣經(jīng)凈化混合加壓后送往燃?xì)廨啓C(jī)燃燒膨脹做功,帶動燃?xì)廨啺l(fā)電機(jī)組發(fā)電。同時燃?xì)廨啓C(jī)排放的高溫?zé)煔饧訜嵊酂徨仩t,產(chǎn)生蒸汽,帶動蒸汽輪發(fā)電機(jī)組,形成聯(lián)合循環(huán)發(fā)電。燃?xì)?mdash;—蒸汽聯(lián)合發(fā)電是熱能資源的梯級綜合利用,其發(fā)電效率高達(dá)45%以上,實(shí)現(xiàn)了鋼電聯(lián)產(chǎn),目前我國的濟(jì)鋼寶鋼太鋼沙鋼通鋼鞍鋼馬鋼邯鋼安鋼漣鋼等多家鋼廠都在使用該技術(shù)。

The basic principle of this technology is to purify, mix and pressurize the remaining coke oven gas and the recovered blast furnace gas, and then send them to the gas turbine for combustion and expansion, driving the gas turbine generator set to generate electricity. At the same time, the high-temperature flue gas emitted by the gas turbine heats the waste heat boiler to generate steam, which drives the steam turbine generator unit and forms a combined cycle power generation. Gas steam combined power generation is an efficient cascade comprehensive utilization of thermal energy resources, with a power generation efficiency of over 45%, achieving joint production of steel and electricity. Currently, this technology is being used by multiple steel plants in China, such as Baosteel, Taiyuan Steel, Shagang, Tonggang, Ansteel, Ma Steel, Han Steel, An Steel, and Liangang.

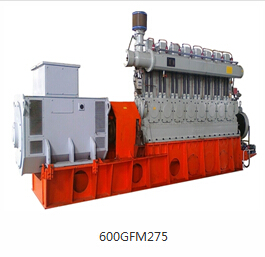

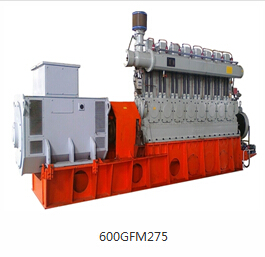

用煤氣內(nèi)燃機(jī)帶動發(fā)電機(jī)發(fā)電

Using a gas internal combustion engine to drive a generator for power generation

我國山東山西寧夏安微河北新疆內(nèi)蒙古云南江蘇等地的一些焦化廠采用煤氣內(nèi)燃機(jī)發(fā)電??晒┻x擇的焦?fàn)t煤氣內(nèi)燃機(jī)發(fā)電機(jī)組有400千瓦500千瓦1200千瓦和2000年瓦。目前焦化行業(yè)大多采用的是500千瓦焦?fàn)t煤氣內(nèi)燃機(jī)發(fā)電機(jī)組。按焦?fàn)t煤氣熱值(低熱值)16720千焦/立方米計算,1立方米焦?fàn)t煤氣可發(fā)電1.1千瓦時。

Some coking plants in Shandong, Shanxi, Ningxia, Anwei, Hebei, Inner Mongolia, Yunnan, Jiangsu, and other areas in China use gas internal combustion engines for power generation. There are 400 kilowatts, 500 kilowatts, 1200 kilowatts, and 2000 kilowatts of coke oven gas internal combustion engine generator sets available for selection. Currently, the coking industry mostly uses 500 kW coke oven gas internal combustion engine generator sets. Calculated based on the calorific value (low calorific value) of coke oven gas at 16720 kilojoules per cubic meter, 1 cubic meter of coke oven gas can generate 1.1 kilowatt hours of electricity.

在線咨詢

在線咨詢 官方二維碼

官方二維碼

當(dāng)前位置:

當(dāng)前位置: 2023.05.27

2023.05.27