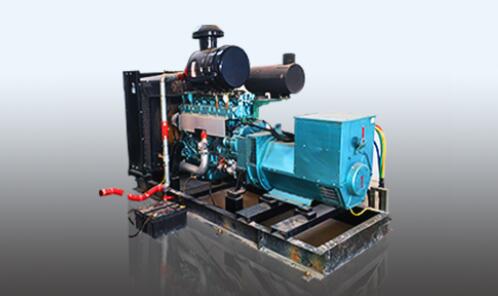

燃?xì)獍l(fā)電機(jī)冷卻水溫度高以及爆震現(xiàn)象分析

大部分的機(jī)器設(shè)備一旦使用時間久了不可避免會出現(xiàn)各式的問題,比如說燃?xì)獍l(fā)電機(jī)冷卻水溫度高以及爆震現(xiàn)象的存在,這就要趕緊進(jìn)行分析原因了,以防止發(fā)生隱患。下面來講講吧。

Once most of the machines and equipment have been used for a long time, various problems will inevitably occur, such as high cooling water temperature of gas generator and the existence of detonation phenomenon. Therefore, it is necessary to analyze the causes to prevent hidden dangers. Let's talk about it.

冷卻水溫度高

High cooling water temperature

現(xiàn)象:站控值班人員發(fā)現(xiàn)燃?xì)獍l(fā)電機(jī)水溫偏高,相關(guān)人員隨即赴現(xiàn)場對發(fā)電機(jī)組進(jìn)行檢查,風(fēng)扇等冷卻系統(tǒng)正常,控制面板無報警。半小時之后,上位機(jī)出現(xiàn)該燃?xì)獍l(fā)電機(jī)冷卻水溫度高報警, 進(jìn)而造成停機(jī)。

Phenomenon: when the station control personnel on duty found that the water temperature of the gas generator was too high, relevant personnel immediately went to the site to inspect the generator set. The cooling systems such as fans were normal, and the control panel did not give an alarm. Half an hour later, the upper computer gave an alarm of high cooling water temperature of the gas generator, resulting in shutdown.

造成此次冷卻水溫度高原因分析:該燃?xì)獍l(fā)電機(jī)正常運(yùn)行時冷卻水溫度在89℃左右,當(dāng)負(fù)載有較大幅度的提升時,冷卻水溫度隨即上升,超過臨界值導(dǎo)致報警停機(jī)。

Cause analysis of the high cooling water temperature: the cooling water temperature of the gas generator is about 89 ℃ during normal operation. When the load is greatly increased, the cooling water temperature rises immediately, exceeding the critical value, resulting in alarm and shutdown.

其他原因分析:

Analysis of other causes:

(1)冷卻水管路存在結(jié)垢現(xiàn)象,導(dǎo)致冷卻水散熱不佳;(2)冷卻風(fēng)扇電機(jī)損壞,導(dǎo)致散熱不佳;(3)節(jié)溫器卡住或者其他原因?qū)е挛创蜷_;(4)冷卻水管路或者接頭處漏水,冷卻水自然損耗液位降低導(dǎo)致冷卻水缺失;(5)冷卻水溫度傳感器故障,導(dǎo)致檢測結(jié)果失準(zhǔn)。

(1) Scaling of cooling water pipeline leads to poor cooling of cooling water; (2) The cooling fan motor is damaged, resulting in poor heat dissipation; (3) Thermostat is stuck or not opened due to other reasons; (4) There is water leakage in the cooling water pipeline or joint, and the natural loss of cooling water causes the loss of cooling water due to the decrease of liquid level; (5) The cooling water temperature sensor is faulty, resulting in inaccurate detection results.

爆震

knock

現(xiàn)象:現(xiàn)場控制屏出現(xiàn)“Knocking”故障報警信息。

Phenomenon: the "knocking" fault alarm message appears on the field control panel.

原因分析:

Cause analysis:

(1)氣缸燃燒室內(nèi)積碳過多,容易在積碳表面形成高溫著火點(diǎn);(2)點(diǎn)火提前角過于提前,導(dǎo)致點(diǎn)火引燃混合燃?xì)獾臅r間早于活塞到達(dá)上止點(diǎn)的時間,從而在活塞壓縮沖程中壓力急劇升高導(dǎo)致爆燃的發(fā)生。

(1) There is too much carbon in the cylinder combustion chamber, which is easy to form high-temperature ignition points on the carbon deposition surface; (2) The ignition advance angle is too early, which causes the ignition time of the mixed gas to be earlier than the time when the piston reaches the top dead center, so the pressure rises sharply in the piston compression stroke, resulting in the occurrence of deflagration.

同時,爆燃產(chǎn)生的壓力作用于活塞,影響活塞的沖程,導(dǎo)致爆震現(xiàn)象;(3)燃?xì)獍l(fā)電機(jī)組冷卻水溫度過高導(dǎo)致發(fā)動機(jī)機(jī)體溫度高,散熱不良,產(chǎn)生高溫而發(fā)生爆震;(4)空燃比不正確等其他情況。

At the same time, the pressure produced by deflagration acts on the piston, affecting the piston stroke and leading to detonation; (3) Excessive cooling water temperature leads to high engine body temperature, poor heat dissipation, high temperature and detonation; (4) Other conditions such as incorrect air-fuel ratio.

以上就是問題解答的相關(guān)內(nèi)容了,希望能夠幫助到大家,如對這一問題還存在任何疑問,都?xì)g迎關(guān)注我們網(wǎng)站http://www.vw95.cn并咨詢我們的工作人員,將竭誠為您服務(wù)。

The above is the relevant content of the question answer. I hope it can help you. If you still have any questions about this problem, you are welcome to follow our website http://www.vw95.cn And consult our staff, will serve you wholeheartedly.

在線咨詢

在線咨詢 官方二維碼

官方二維碼

當(dāng)前位置:

當(dāng)前位置: 2022.06.23

2022.06.23